TECHNICAL INFORMATION • 13/12/2021

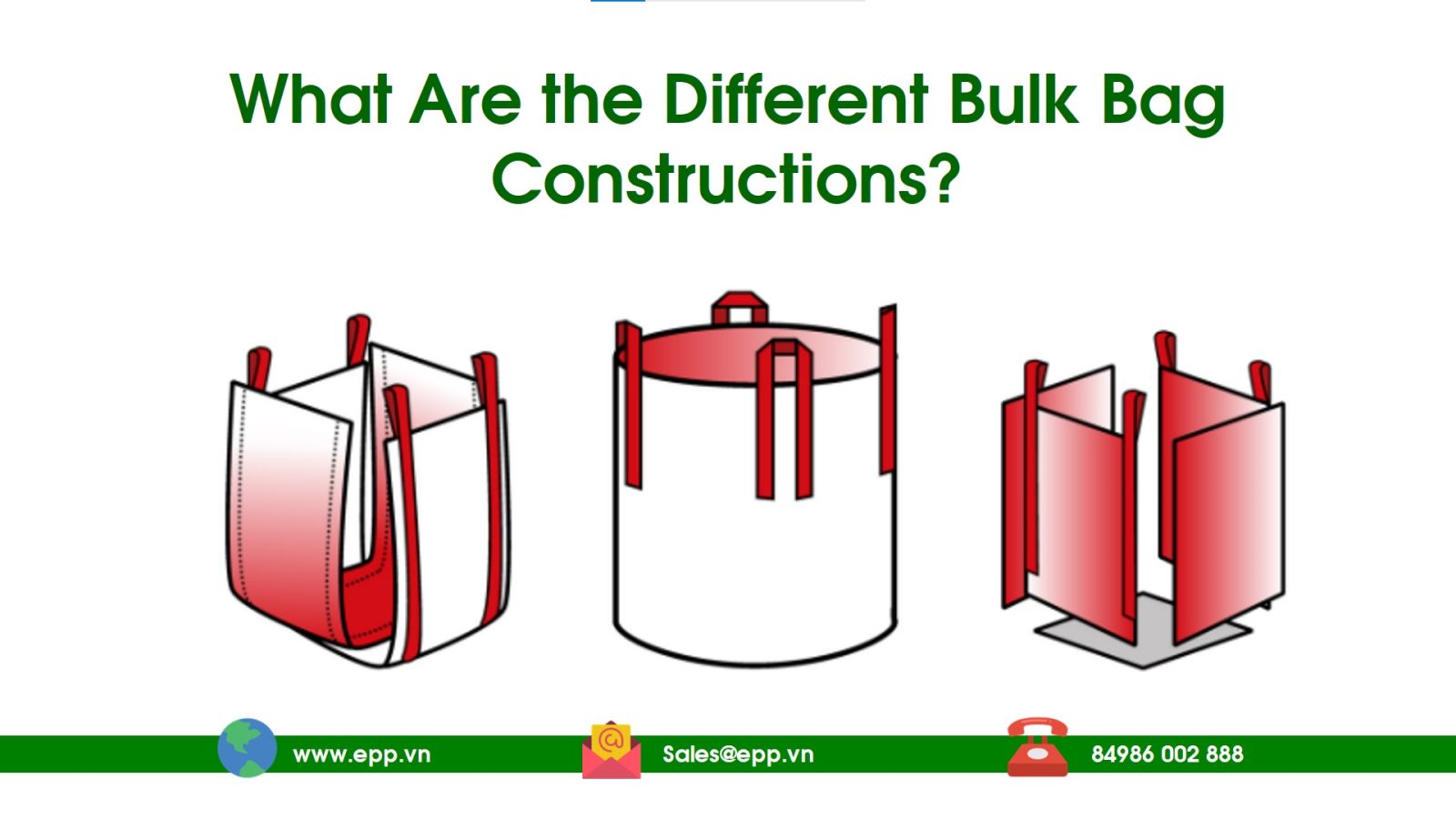

FIBC Bag construction refers to the way that the sheets of woven polypropylene are sewn/stitched together to form a bag. There are several different construction types and these types can have a big impact on the SWL (safe working load), industry applications, and safe handling of the bag. There are 3 main constructions of FIBCs that are ideal for different storage requirements, as well as being cost-effective. Keep reading to learn the differences between them, as well as help you to determine which type may be more suited to your bulk packaging needs.

.jpg)